Does testing equipment really have to be boring ?

In our daily work we sample and test raw materials and make little notes of numbers and set check marks and so on. We save all this is here and there in different systems, and keep it for many years. It is boring, but neccessary.

It is just a little bit less boring when we get to test equipment. We’ll write up the test plan -or simply refer to a predefined tes layed out by, say, a European Norm- and send the equipment to an independant 3rd party laboratory. For formal certification we will even use a certified, accredited laboratory. After some time, we get the equipment back with a report and/or a certificate. Again, it is all numbers and check marks, and quite frankly: It’s boring.

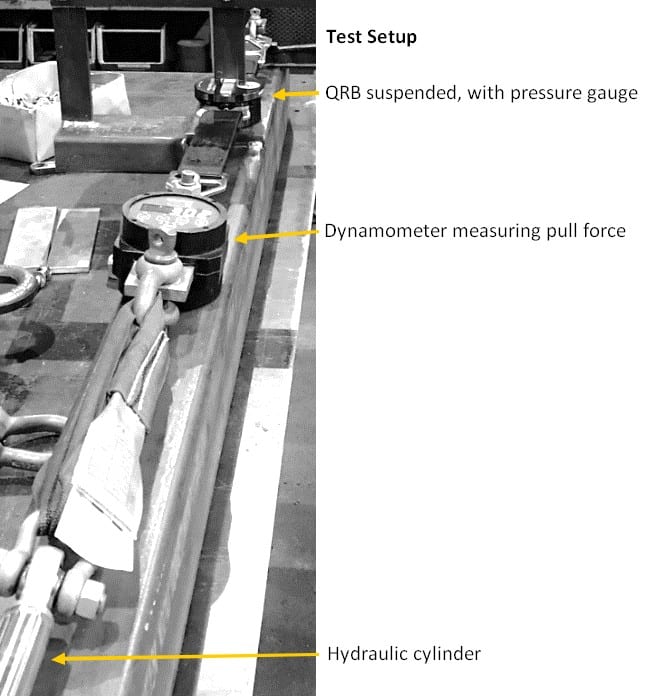

For example, on a regular basis we send our Quick Release Box (QRB) to a laboratory. Here it will be set up in a hydraulic pull test apparatus and increasing force is applied. At intervals it is tested if the QRB are able to release as intended. Surely, it results in more numbers and check marks, but it is still boring. Just take a look at the test setup, and you’ll know what we mean.

Other test have the purpose of demonstrating a certain breaking strength. For hoist equipment it is often a question of finding the weakest link. It makes a lot of impressing noise when a harness is ripped to pieces at 35 kN (equal to 3670 kg or 7870 lbf) or when a piece of hardware give up at 46 kN (~ 4690kg / 10300 lbf), but it still ends up in boring numbers.

And more important, numbers are not always of any particular interest, except when needed to prove compliance with a certain specification, regulation or standard. Some times it is much more interesting and fun, when we get to test equipment in real life or in a controlled, simulated environment and simply check and see with our own eyes if this or that piece of equipment is working as intended.

This summer we spend a few days in sunny Spain, playing with the “release under tension” of our QRB. And yes, we did keep social distance and so on, no need to ask 🙂

Day one – In the pool

The pool offers great light for filming, but even when pulling hard, it is kind of slow motion. Feels like being little kids in a playground, having a lot of fun. No more words, just go and check the video of Day 1 …

Day two – At the sea

The sea offers more space for high speed pulling, simulating a “engine failure fly away”. You may call it something different, but you do know what we mean, right ? Anyway, the recipe is quite simple: Take a speed boat, 10 meters of nylon rope, a camera and a test dummy, tie everything together, add some thrust and have fun.

The result is clear: The QRB is able release under tension, exactly as it is intended to. Check the video of Day 2 …